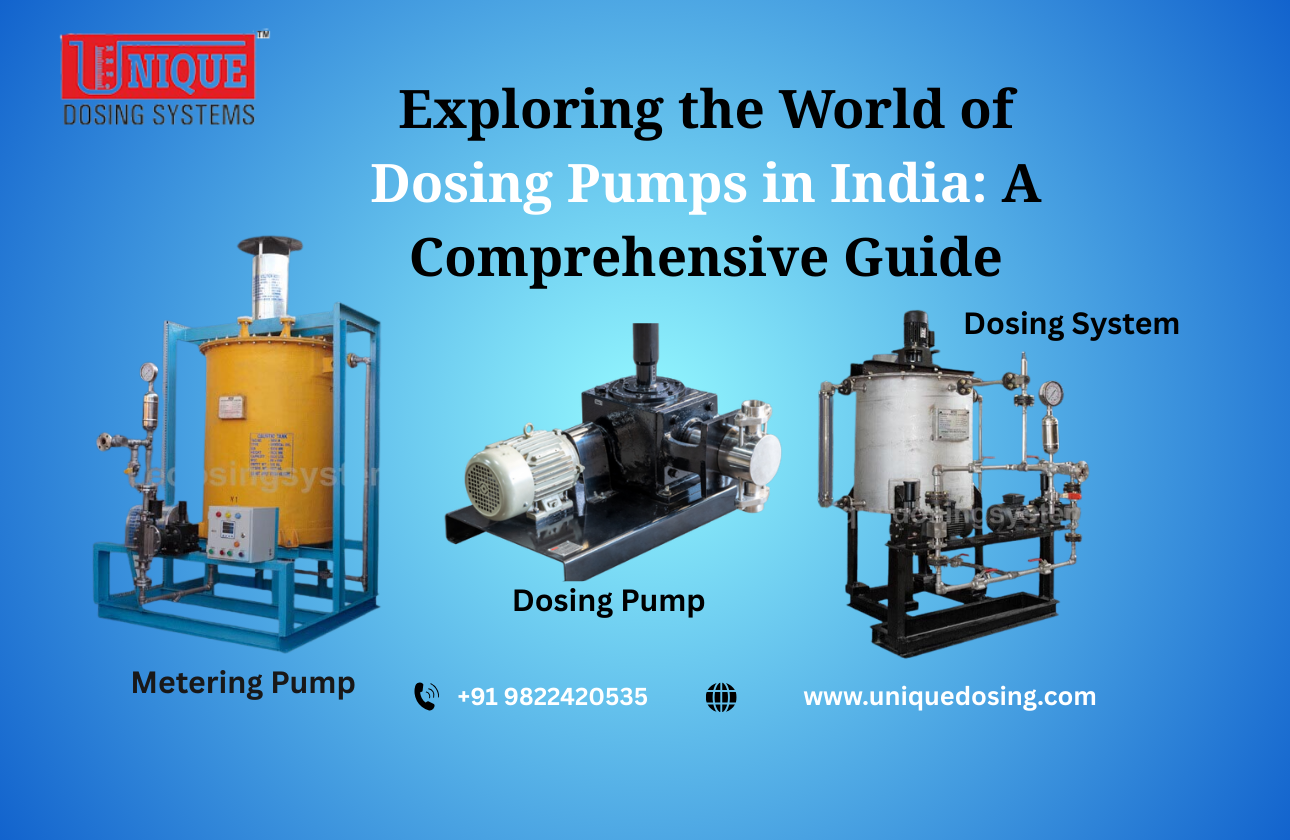

Introduction to Dosing Pumps in India

Dosing pumps, also known as metering pumps or chemical injectors, are vital components in numerous industries across India. They are intricately designed to provide accurate and consistent dosing of liquids, such as chemicals, acids, or any other fluid, into a system or process. This precision makes them indispensable in sectors such as water treatment, chemical manufacturing, food, and pharmaceuticals.

The Importance of Metering Pumps

Metering pumps are a specific type of dosing pump that is specifically designed to dispense a precise, preset volume of liquid. These pumps are crucial for maintaining the delicate balance of chemical solutions used in various industrial processes. The pumps assure accuracy and control, which are critical factors in industries where even the slightest deviation can lead to significant quality issues or safety hazards.

Advantages of Metering Pumps

Metering pumps offer numerous advantages, including:

- Accuracy: They ensure precise fluid control, essential in manufacturing and processing operations.

- Versatility: Metering pumps are adaptable to a wide range of liquids, including corrosive and viscous substances.

- Consistency: They provide uninterrupted and reliable operation, critical in continuous processing industries.

- Safety: These pumps help in safely moving hazardous chemicals, reducing the risk of spills or accidents.

Understanding Dosing Systems

A dosing system is an assembly that includes one or more dosing pumps and other necessary components to facilitate the precise delivery of chemicals. These systems integrate various technologies such as flow meters, controllers, and pressure regulators to ensure accurate and automated dosing in various applications.

Components of Dosing Systems

Dosing systems typically consist of:

- Dosing Pumps: The central element in the dosing system that pumps and controls fluid dosage.

- Storage Tanks: These store the chemical or fluid that is to be dosed.

- Mixing Equipment: Used in applications requiring a homogenous mixture.

- Control Units: These ensure accurate dosing as per the required process parameters.

Industry Applications in India

In India, dosing pumps and systems are widely utilized across various industries:

- Water Treatment: For the dosing of chemicals such as chlorine and flocculants to ensure clean water supply.

- Food and Beverage: Used to add precise flavors, preservatives, or colorings while maintaining food safety standards.

- Pharmaceuticals: Essential for the precise formulation of medications.

- Chemical Manufacturing: Ensures consistent quality in chemical production processes.

Conclusion

Dosing pumps in india, including metering pumps and comprehensive dosing systems, play a pivotal role in Indian industries. Their precision, reliability, and efficiency in handling diverse and often hazardous fluids make them an invaluable asset. As India continues to industrialize, the demand for these pumps and systems is expected to grow, paving the way for technological advancements and enhanced industry performance.

Published on November 27, 2025 by Admin