Understanding Dosing Systems and the Role of Dosing and Metering Pumps

Dosing systems play a vital role in various industries, from water treatment to chemical processing. They ensure precise measurement and delivery of fluids, which is essential for maintaining efficient and safe operations. The components of these systems, particularly dosing pumps and metering pumps, are at the heart of their functionality.

What is a Dosing System?

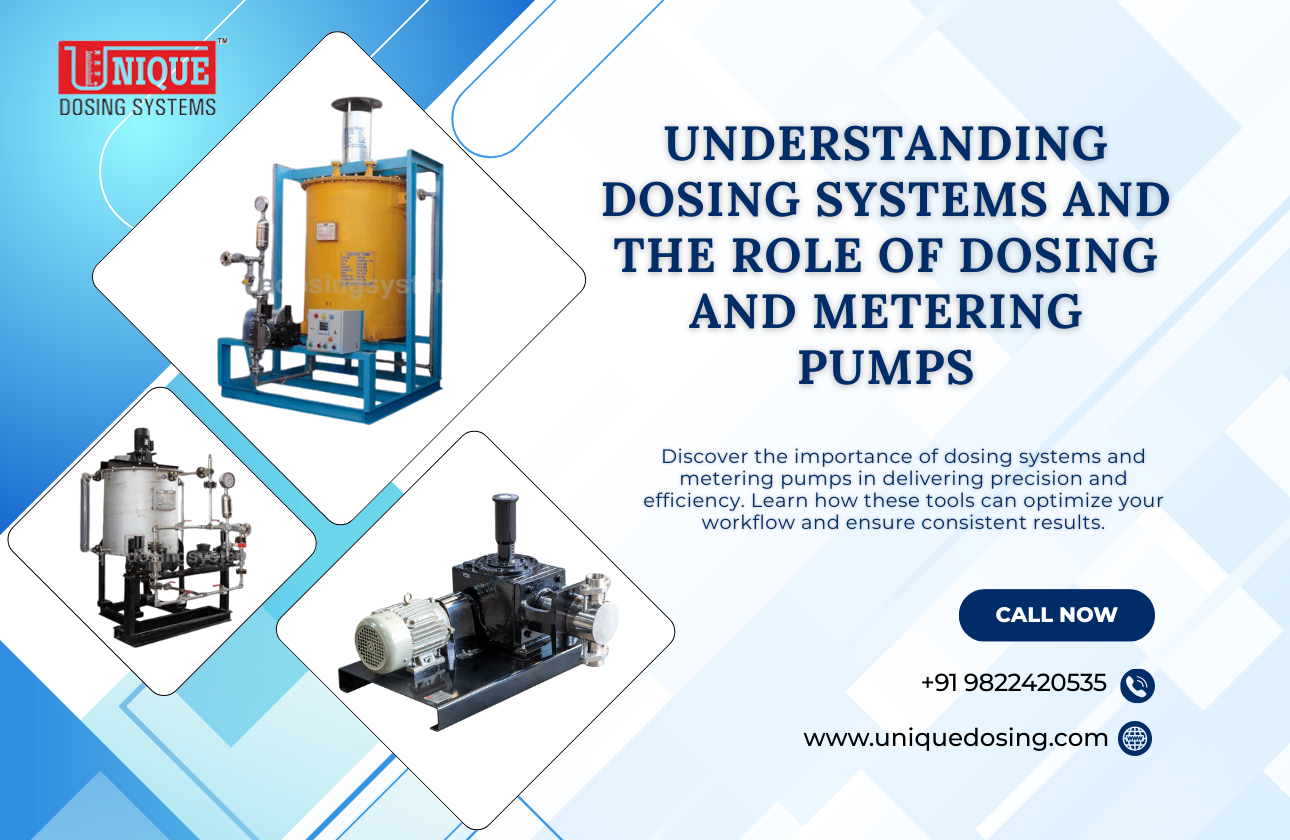

A dosing system is a setup that ensures liquids are delivered in specified quantities. These systems are indispensable when precise dosages are required, providing control and efficiency in applications ranging from industrial to agricultural sectors. Typically, they consist of several principal components, including pumps, controllers, and storage tanks, that work in unison to achieve the desired flow rates and volumes.

The Functionality of Dosing Pumps

Dosing pump, the cornerstone of dosing systems, are designed to deliver exact amounts of fluid into a system. They operate under varying pressure conditions, which makes them suitable for industries where precision is paramount. These pumps are versatile and can handle a wide range of substances, including chemicals, nutrients, and other liquids.

In practice, a dosing pump works by drawing a specific volume of liquid and then injecting it into a process. The accuracy of the dosage is maintained by adjusting the stroke length or the frequency of the pump's operation. This precision is critical in applications where even slight deviations could lead to significant consequences.

Exploring Metering Pumps

Metering pumps are a subset of dosing pumps characterized by their precise flow control capabilities. They are designed to move a precise volume of liquid over a certain period, thus providing an accurate and repeatable flow rate. The mechanisms of metering pumps typically involve either diaphragm, peristaltic, or piston configurations, each offering specific advantages depending on the application.

Industries that require rigorous chemical management, such as pharmaceutical or water treatment, often rely heavily on metering pump. Their ability to ensure consistent delivery of chemicals helps maintain the integrity of the processes they support.

Choosing the Right System for Your Needs

Selecting the right dosing system involves careful evaluation of the specific requirements of your application. Factors like the nature of the fluids, the required flow rate, and environmental conditions play a critical role in determining the appropriate equipment. Consultation with experts and consideration of the latest innovations in pump technology can provide significant benefits in terms of reliability and efficiency.

Conclusion

Understanding the intricacies of dosing systems is essential for anyone involved in process management. Dosing pumps and metering pumps are critical components that facilitate precise fluid control and delivery, enhancing overall operational efficiency. By leveraging these tools, industries can ensure optimal performance, safety, and compliance with regulatory standards.

Published on December 23, 2025 by Admin